Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

On Friday, October 3rd, a fleet of pint-sized autonomous delivery robots barreled into the streets of New York City, carrying parcels for the first time in a full‑scale commercial pilot launched by logistics giant UrbanPack. The robots completed a 10‑mile circuit, avoiding pedestrians, potholes, and busy crosswalks with a confidence that sparked a flurry of media headlines and social‑media chatter. This high‑profile event underscores a broader tech wave propelling the next generation of urban mobility: the explosive surge in autonomous delivery systems. Behind the sleek exteriors and impressive navigation algorithms lies a cornerstone of mechanical engineering that is quietly pulling the leg: the gear motor, also known as a reducer motor.

While consumers may marvel at the robots’ lidless ID badges and colorful LED displays, the real hero is the gear motor—an indispensable component that delivers the torque, speed control, and durability required for the delicate choreography of urban delivery. In this article we’ll explore why the robot frontier has become the new arena for gear motor innovation, and how this humble device is poised to shape the future of last‑mile logistics.

Last year, the global shipping industry experienced record orders for electric delivery vans and drones, accelerated by a COVID‑19‑induced shift toward e‑commerce. In 2025, the United Nations Inter‑governmental Panel on Climate Change (IPCC) estimated that 45% of future freight by weight will be handled by autonomous robots to cut CO₂ emissions. Major cities across North America, Asia, and Europe are running pilot programs to replace manual couriers with electrically powered robots that can navigate sidewalks and alleyways autonomously.

Tech giants—Amazon, Alphabet’s Wing, and dozens of robotics startups—have unveiled fleets of "last‑mile drones" and "ground bots" that combine GPS positioning, machine‑vision, and lightweight batteries. Market analysts predict a global market for autonomous delivery robots that will surpass $30 billion by 2030, with automotive and industrial suppliers scrambling to scale the required components.

At the core of every robotic platform lies a set of electric motors that convert stored electrical energy into mechanical motion. For robots that must be both lightweight and powerful—think a 40‑pound delivery bot that can accelerate from 0 to 3 mph in a few seconds—a single motor is often insufficient. Automotive engineers have long overcome this challenge with a gear motor: a compact motor paired with a reduction gearbox that lowers the motor’s high rpm output to a low‑speed, high‑torque value while boosting the overall efficiency.

Key benefits of gear motors for autonomous delivery robots include:

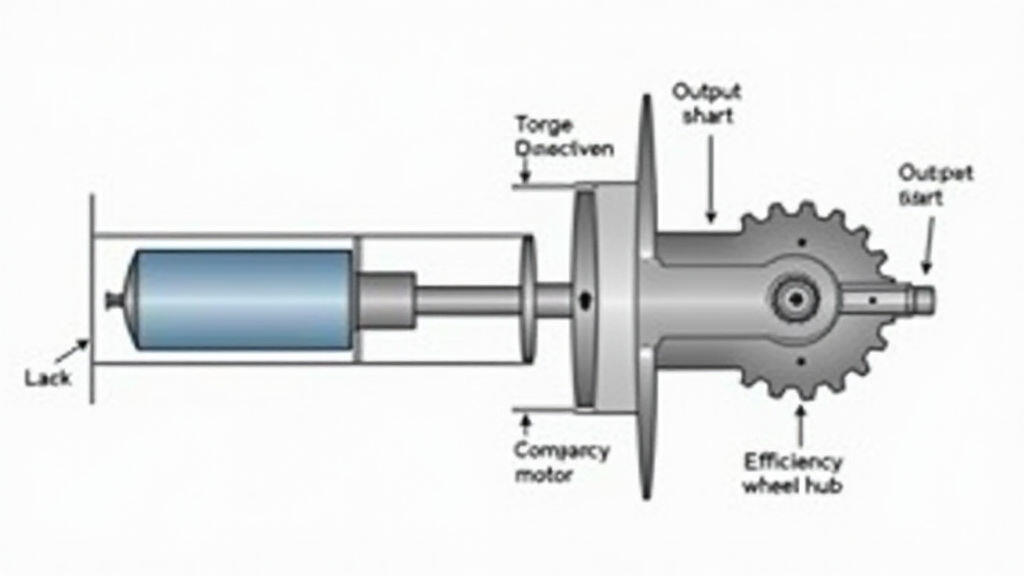

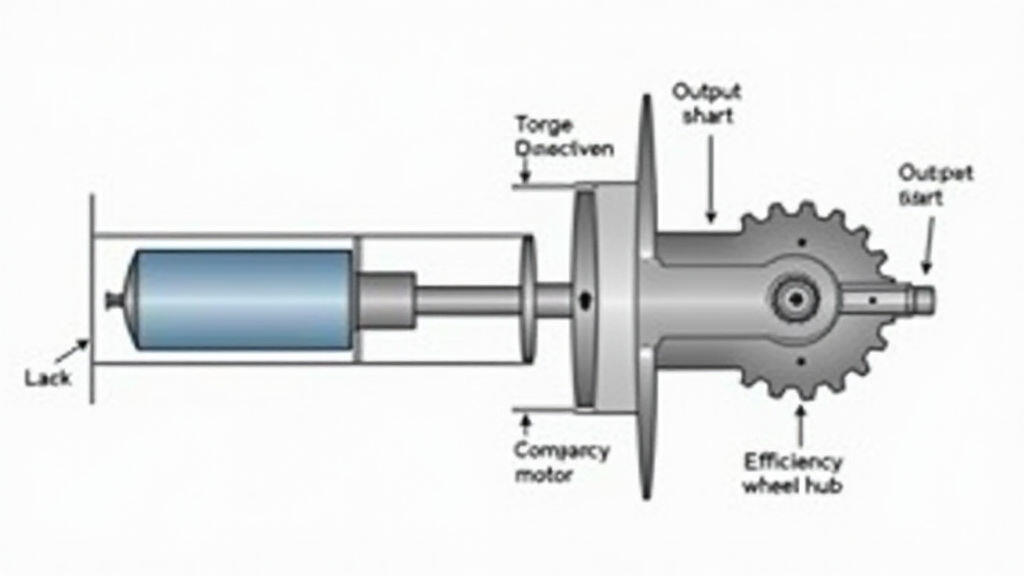

Below is a simplified schematic of an integrated gear motor used in a delivery robot’s drive system.

In many fleets, each robot houses two or four gear motors—one per wheel or sometimes one motor drives a single integrated hub propelling the robot via a castor wheel. The compactness and ruggedness of these motors match the demands of up to 12 hours of continuous operation in varied weather conditions.

The influx of autonomous delivery programs has spurred a new wave of gear motor design tailored for robotics. Smart manufacturers now focus on lightweight materials, such as aluminum alloy housings and carbon‑fiber housing options, to shave off grams while maintaining structural integrity.

“We’ve condensed performance by 30% by shifting from a conventional steel gear train to a micro‑inclusion ceramic‑reinforced plastic gear,” says Li Chen, chief engineer at Geartronix. “That weight savings translates to battery life extension and lower collision risk.”

Moreover, automation in the manufacturing of gear motors—using injection‑molded internal gear housings and robotic assembly lines—has reduced costs by an estimated 15% compared to traditional gearboxes. This price advantage is critical when a logistics provider orders thousands of units for a nationwide deployment.

From a cost perspective, reducing weight via premium gear motor designs directly lessens payload limitation, allowing each robot to carry larger packages. That generates higher revenue per trip and quicker return on investment for logistic firms.

Environmentally, gear motors’ higher efficiency reduces the energy consumption of each robot by up to 20% over a standard steel reduction gear set. When multiplied across millions of deliveries, the cumulative fuel‑savings are equivalent to thousands of electric cars retiring from the road.

Government incentives for low‑emission logistics are also boosting demand for high‑efficiency gear motors. In California, the Low‑Carbon Shipping Initiative grants tax rebates for fleets that achieve specified energy‑use thresholds—an incentive cohort that heavily features advanced gear motor solutions.

While autonomous delivery robots are the most visible estimator of demand, the traction gained by gear motors in this domain will ripple into other fields. Autonomous forklifts, warehouse AGVs (Automated Guided Vehicles), and even self‑driving construction equipment are beginning to prefer integrated gear motors due to their combined space and power advantages.

Research is moving toward brushless DC gear motors that minimize maintenance and extend operation times. Additionally, hybrid systems that pair gear motors with supercapacitors hold promise for rapid energy recovery during braking—a concept that could further reduce power consumption in stop‑and‑go delivery operations.

The April 2025 rollout of autonomous delivery robots across North America has spotlighted a silent but critical player: the gear motor. Its ability to deliver high torque, maintain compactness, and increase power efficiency aligns perfectly with the demands of next‑generation urban logistics. As cities embrace autonomous delivery, governments push for greener freight solutions, and manufacturers innovate faster, the gear motor stands poised to become the backbone of an efficient, sustainable last‑mile ecosystem.

In the coming years, we can expect more robust, lighter, and smarter gear motors, enabling robots to accelerate, migrate, and deliver with unprecedented autonomy and reliability. The trend is clear—autonomous delivery may be the phenomenon that propels gear motors from background components to flagship products in the age of intelligent logistics.

Leave A Reply

Your email address will not be published. Required fiels are marked